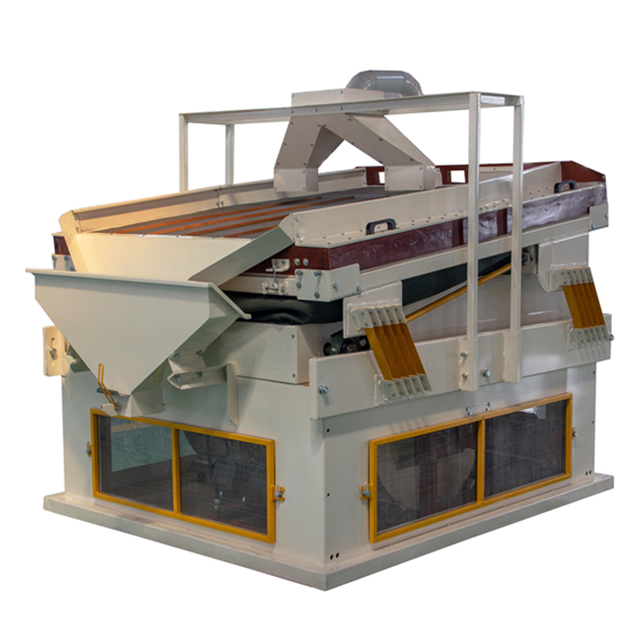

Professional China Gravity Separator Machine - 5XZ-10 soybean mung bean sesame Gravity separator separating machine – SYNMEC

Professional China Gravity Separator Machine - 5XZ-10 soybean mung bean sesame Gravity separator separating machine – SYNMEC Detail:

Introduction and Application:

5XZ-10 gravity separator is used for fine cleaning and impurity separation of seeds and beans with identical particle size but with differences in their specific weight.

The Gravity Separator is used to remove partially eaten, immature, insect damaged sick seed and moldy seed from good seed, which traditional cleaning method by Seed Cleaner and Indented cylinder prove to be less effective.

The Gravity Separator is suitable for efficient cleaning all cereals, grains ,pulses ,beans and seeds of all crops such as wheat, paddy, barely, maize, millets, sunflower seed, soybean, rice, quinoa seed, chia seed. oil seeds ,sesame , clover seed, vegetable seed etc.

Specification:

| Capacity (Count by wheat) | 10000 kg/h |

| Sieve Table Size | 3900*1550 mm |

| Total Power | 15 KW |

| Motor for build-in Air Blower | Six air blowers (1.5KW*3 + 1.8KW*3 = 9.9 KW) |

| Motor for vibration | Y132M1-4, 4.0 KW (the vibration speed of deck can be adjusted by frequency converter from 0-480r/m) |

| Motor for Good Grain Release | Y90S-4 , 1.1 KW |

| Lateral angle of inclination | 3°~6° |

| Longitudinal angle of inclination | 0~6° |

| Amplitude | 7mm |

| Dimension (L*W*H) | 4300×1960×2500 mm |

| Weight | 2500 kg |

Working Process:

The seeds or beans are fed continuously on the vibration deck surface of the Gravity Separator, and then spread and makes a uniform bed of material over the deck surface on stratifying area.

In stratifying area, by the function of uniform air system the light materials will go top of product bed and heavy material will go lower under the light materials and touch the deck surface.

The vibration deck is supported by a eccentric drive which makes the deck to move in high frequency and low amplitude. And the heavy materials will move up towards higher position of deck, while light materials move down towards lower position of deck. And in this process also generate of mixed materials which will be discharge from middle outlet .At the same time, some heavier gravity like stones will be discharged separately.

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Professional China Gravity Separator Machine - 5XZ-10 soybean mung bean sesame Gravity separator separating machine – SYNMEC , The product will supply to all over the world, such as: Tunisia , Mexico , Morocco , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.