Professional China Coffee Bean Processing Plant - 5XZS-10DGT Seed Cleaning & Processing Machine – SYNMEC

Professional China Coffee Bean Processing Plant - 5XZS-10DGT Seed Cleaning & Processing Machine – SYNMEC Detail:

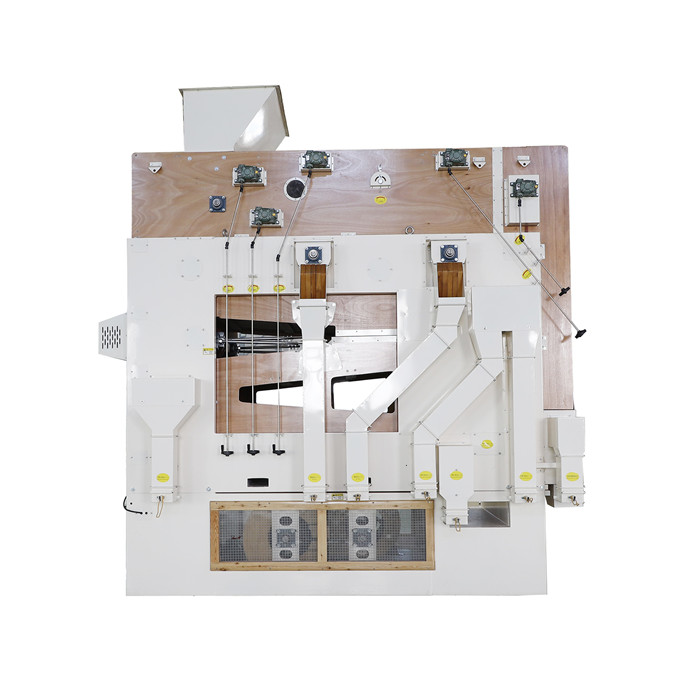

The 5XZS-10DGT Seed Cleaning & processing machine is uniquely designed with air cleaning, gravity separating, vibratory sieve separating and grading maximizing the cleaning efficiency, minimizing the wear and tear and ease of removability & changeability.

Technical Data:

| Model: | 5XZS-10DGT |

| Function: | Wheat hulling (optional), air cleaning, pre-cleaning by two layers sieving trunks, two time gravity separating and four sieve layers fine sieve cleaning. |

| Size: | 8600X2300X3600mm |

| Capacity: | 10 ton/hour for seeds (count on wheat) |

| Cleaning rate: | >97% |

| Sieve cleaning type: | Rubber ball vibration |

| Noise: | <85dB |

| Electricity input: | 3 phase |

| Power: | 31.1Kw Wheat huller motor : 7.5Kw Bucket elevator: 1.1Kw Top air blower: 5.5Kw Pre-cleaner vibration motor:0.25Kw X 2 sets Gravity table: 7.5Kw X 2 sets Main sieving trunk vibration motor:0.75Kw X 2 sets |

Feature:

5XZS-10DGT Seed Cleaning & Processing Machine is designed with wheat hulling, air cleaning, pre-cleaning by two layers sieving trunk, two times gravity separating, vibration sieve cleaning and grading. This model consists of so many functions on one mobile type seed cleaner make it ideal for wider application.

Structure:

Multi functions combined in one machine

1.Wheat huller 2. Two sieving trunks 3. Air aspirator 4. Two Gravity tables 5. Air cleaning

Working flow:

Wheat are fed into wheat huller to hulling, then lifted up by bucket elevator, enter to pre-cleaning vibratory sieving trunk for quick removing small, large impurity, and light impurity, then wheat enter to two gravity tables for removing the bad seed (partially eaten, immature, insect damaged, sick seed, etc. ). Finally wheat enters to the second vibratory sieving trunk for removing oversized & undersize impurity again, also grading seed to different sizes. Wheat from outs becomes seed which can be sowed in ground directly.

Product detail pictures:

Related Product Guide:

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Professional China Coffee Bean Processing Plant - 5XZS-10DGT Seed Cleaning & Processing Machine – SYNMEC , The product will supply to all over the world, such as: Armenia , Ukraine , Lyon , Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!