Manufacturer for Grain Seed Processing Plant - 5XZS-20DS seed cleaner grain cleaning machine for sesame maize sorghum – SYNMEC

Manufacturer for Grain Seed Processing Plant - 5XZS-20DS seed cleaner grain cleaning machine for sesame maize sorghum – SYNMEC Detail:

Introduction:

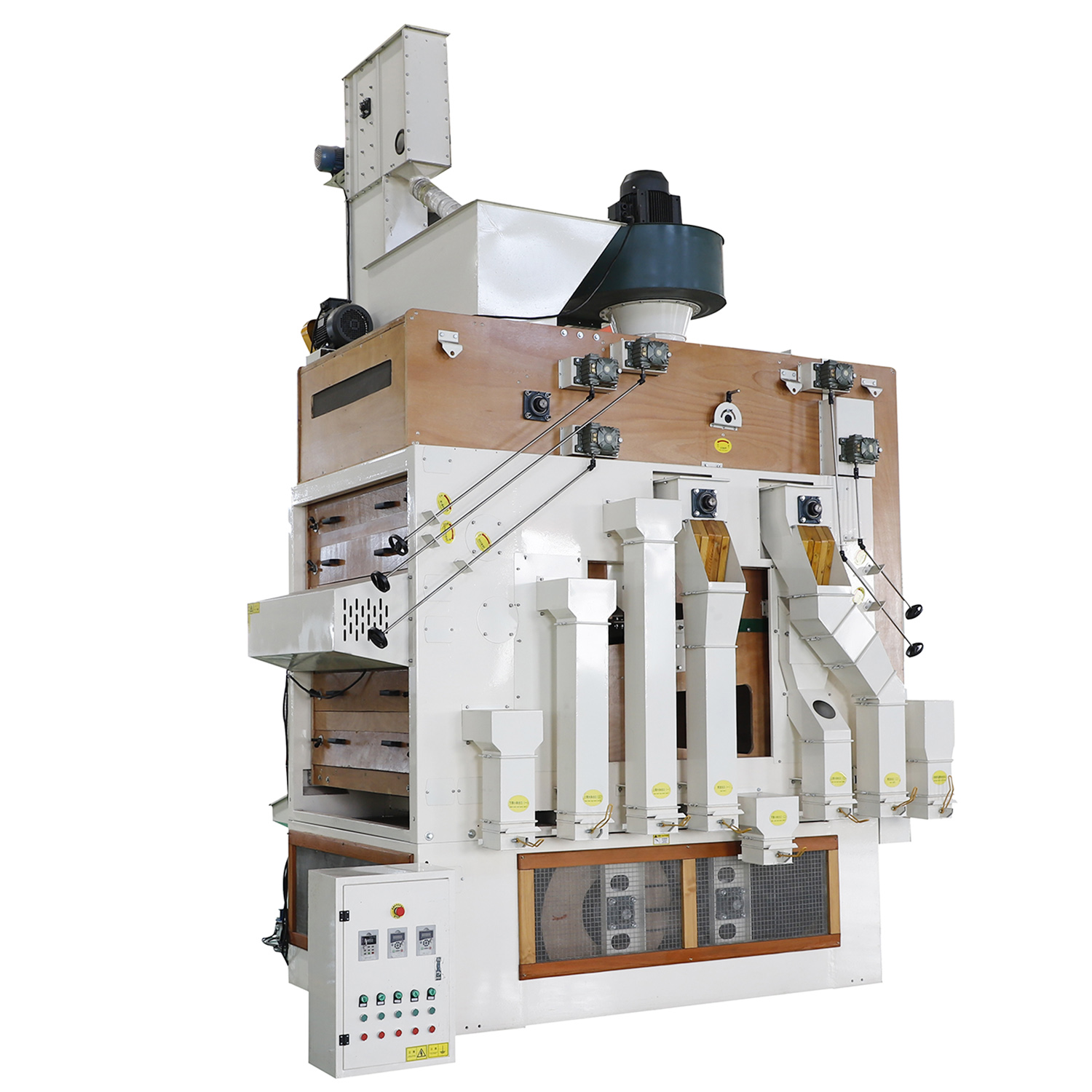

The 5XZS Seed Cleaning & processing machine is uniquely designed with wheat hulling, air cleaning, gravity separating, vibratory sieve separating and grading maximizing the cleaning efficiency, minimizing the wear and tear and ease of removability & changeability, it is a patent product in 2014.

The intake hopper enables wheat filling into the wheat huller to hulling the wheat, following lifting up by the bucket elevator to enter to the vibratory air cleaning chamber, which is patent design and lead to the best air cleaning efficiency, then the air cleaned wheat enter to the gravity separator for remove the bad seed (partially eaten, immature, insect damaged, sick seed,, etc), then enter to the vibratory sieve for remove the large and small impurity, also grading your seed to different levels by size. The grain after processed by that machine, it will become seed which can be sowing.

Note: .When you process other grains (not wheat), you can put the grain into the hopper of bucket elevator straight way, and turn off the wheat huller. We also have other model available which without wheat huller such as 5XZS-5DS Seed Cleaning & Processing Machine.

Technical Data:

| Model: | 5XZS-20DS |

| Function: | air cleaning, sieve cleaning, gravity separation |

| Size: | 4730X2500X3830mm |

| Capacity: | 20 ton/hour for seeds (count on wheat) |

| Cleaning rate: | >97% |

| Sieve cleaning type: | Rubber ball vibration |

| Noise: | <85dB |

| Electricity input: | 3 phase |

| Power: | Total: 21.49KW Bucket elevator: 1.5KW Top air blower: 11KW Vibration motor: 0.37KW X 2 sets Gravity table air blower: 7.5KW Air closer: 0.75KW |

Feature:

5XZS-20DS Seed Cleaning & Processing Machine has double air cleaning, sieve cleaning, and gravity separating functions. This model consists of so many functions on one mobile type seed cleaner make it ideal for wider application. And it has 20 ton per hour capacity, which is popular for grain cleaning section.

5XZS-20DS Seed Cleaning & Processing Machine Construction and working flow

Multi functions combined in one machine

1. Air aspirator 2. Seed cleaner 3. Gravity table

First of all bucket elevator transfer the grain / seed to the sieving trunk for remove undersize and oversize impurities. There are two air cleaning chambers at the both ends of the sieving. The air cleaning system will remove the light impurity from grain twice before grain flow to gravity table. Finally grain seed enter to the gravity table for remove the bad seeds.

Product detail pictures:

Related Product Guide:

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for Manufacturer for Grain Seed Processing Plant - 5XZS-20DS seed cleaner grain cleaning machine for sesame maize sorghum – SYNMEC , The product will supply to all over the world, such as: Suriname , Ghana , Sevilla , Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!