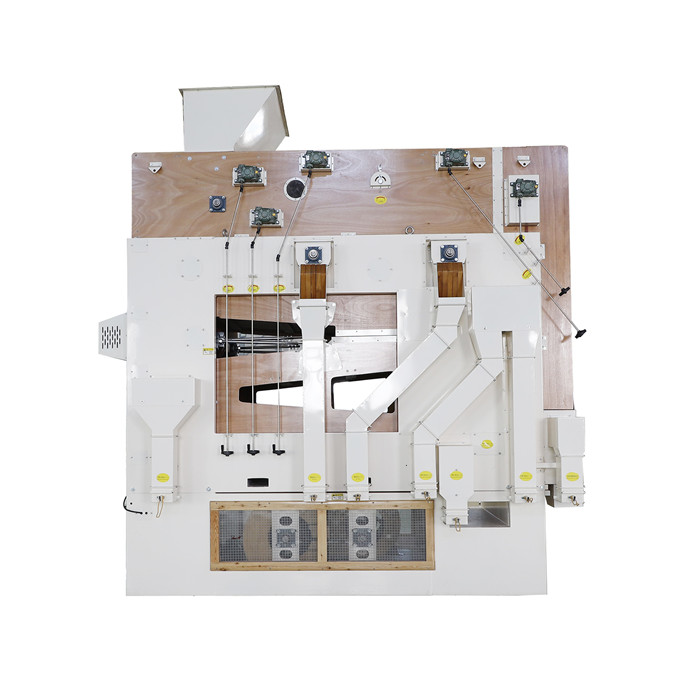

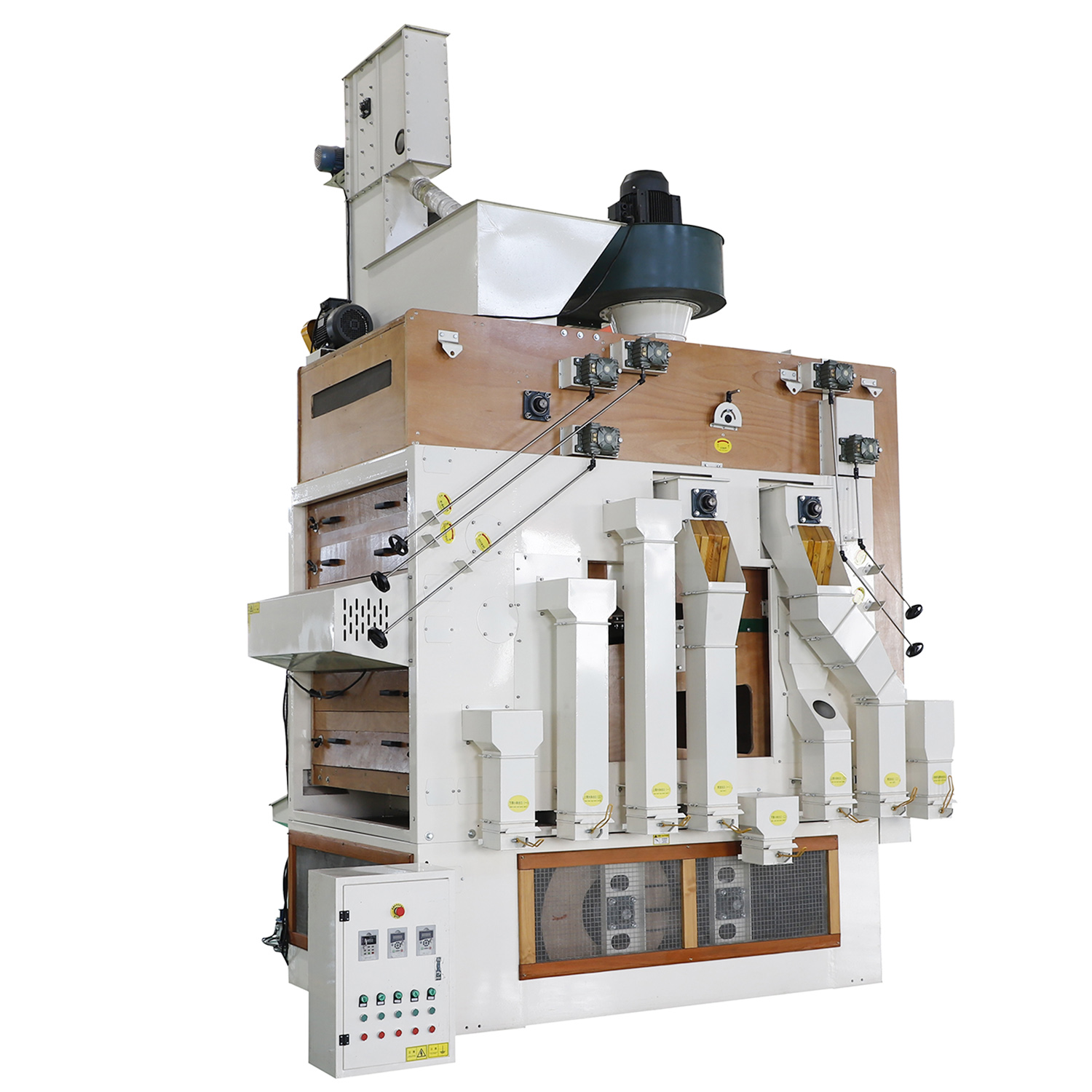

Grain Bean Plane Rotary Cleaner Grader

Material falls on sieve layers and was separated by sieves according to width and thickness difference. All the oversize and undersize impurities were discharged from different outlets.

The air aspiration system is optional, dust and light impurity can be removed by aspirator fan and collected by cyclone dust separator.

FEATURES

1. Suitable for medium and small capacity processing lines

2. Dual screen decks for flexible processes

3. Reliable screen deck compressing and locking mechanism

4. FRP sticks suspension structure for easy adjustment of process parameters

5. Heavy duty structure for durability and reliability

6.Combined material flow routes to accomplish circle, oval and straight movement for high productivity

7. Large sight glass for easy observation of processing status

8. Laser cutting applies to sheet metal components for quality and accuracy

9. Carbon dioxide gas shielded welding workmanship

10. CNC machining centres ensure precise fabrication

11. Powder coated parts and components for best quality and duration

Technical Parameter

| Model | 5XZR-100/200D | 5XZR-125/200T | 5XZR-150/200Q | 5XZR-150/200DD |

| Capacity(t/h) | 6-9 | 7.5-10 | 11-15 | 15-20 |

| Screen Layers | 2 | 3 | 4 | 2 and 2 |

| Screen Width | 1000 mm | 125 mm | 1500 mm | 1500 mm |

| Screen Length | 2000 mm | 2000 mm | 2000 mm | 2000 mm |

| Power (kW) | 1.1 | 1.5 | 2.2 | 2.2 |

| Weight (kg) | 700 | 900 | 1200 | 1250 |

| Size (L*W*H mm) | 2500*1600*1200 | 2500*1850*1350 | 2500*2100*1500 | 2500*2100*1550 |