Good Quality Seed Processing Machine - Seed Cleaning & Processing Machine 5XZS-10DS – SYNMEC

Good Quality Seed Processing Machine - Seed Cleaning & Processing Machine 5XZS-10DS – SYNMEC Detail:

Introduction:

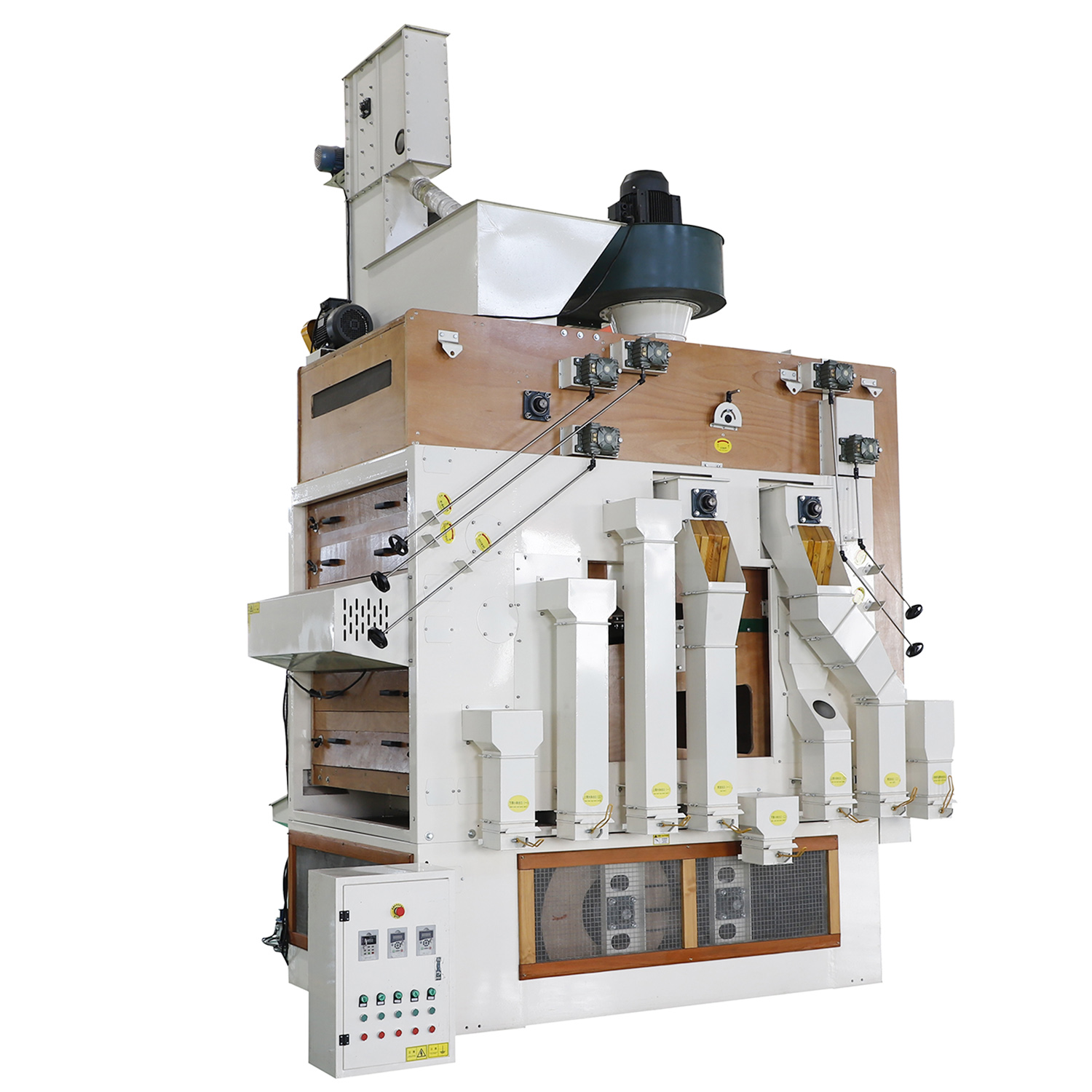

The 5XZS-10DS Seed Cleaning & Processing Machine`s function: wheat hulling (optional), air cleaning, vibration sieve pre-cleaning, gravity separating and vibration sieve fine cleaning.

5XZS-10DS Seed Cleaning & Processing Machine

Wheat are fed into wheat huller (optional) to shell, then lifted up by bucket elevator, enter to small vibratory sieving trunk for quick removing small, large impurity, and light impurity, then wheat enter to gravity table for removing the bad seed (partially eaten, immature, insect damaged, sick seed, etc. ). Finally wheat enters to the vibratory sieving trunk for removing large & small impurity again, also grading seed to different size ranks. Wheat from outs becomes seed which can be sowed in ground directly.

Technical Data:

| Model: | 5XZS-10DS |

| Function: | Air cleaning, pre-cleaning, gravity separation, vibration sieves cleaning & grading. |

| Size: | 6470X2200X3600mm |

| Capacity: | 10 ton/hour for seeds (count on wheat) |

| Cleaning rate: | >97% |

| Sieve cleaning type: | Rubber ball vibration |

| Noise: | <85dB |

| Electricity input: | 3 phase |

| Power: | Total: 15.75Kw Bucket elevator: 0.75Kw Pre-cleaner vibration motor: 0.25Kw X 2 sets Top air blower: 5.5Kw Gravity table : 7.5Kw Main sieving trunk vibration motor: 0.75Kw X 2 sets |

Feature:

5XZS-10DS Seed Cleaning & Processing Machine is designed with air cleaning, pre-cleaning, gravity separating, vibration sieve cleaning and grading. This model consists of so many functions on one mobile type seed cleaner make it ideal for wider application.

Multi functions combined in one machine

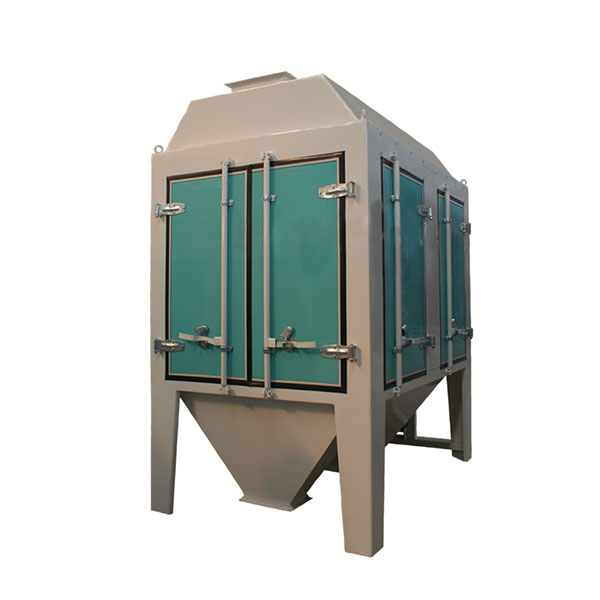

1. Pre-cleaner 2. Air aspirator 3. Gravity table 4. Sieving trunk

Working flow:

The intake hopper enables wheat filling into the wheat huller for hulling the wheat. Then wheat fed from bucket elevator hopper is transported to pre-cleaner. After quick remove the undersize and oversize impurities, then seeds drop to air cleaning chamber for remove light impurity and dust. The big air cleaning chamber will bring the best air cleaning efficiency. Then the air cleaned material enters to the gravity separator for remove the bad seeds (partially eaten, immature, insect damaged, sick seeds, etc). After been processed by gravity separator, seed will comes to the two in one vibratory sieving trunk to remove the large and small impurity. The customer also can select four sieve layers sieving trunk which not only remove the large and small impurity, but also grading the seed to three levels by size (large, medium and small).

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Good Quality Seed Processing Machine - Seed Cleaning & Processing Machine 5XZS-10DS – SYNMEC , The product will supply to all over the world, such as: Belgium , Iran , Rwanda , We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.