Factory wholesale Bean Seed Cleaning Machine - 5X-12 fine seed cleaner /grain seed cleaning machine for sesame chia seed sorghum soybean – SYNMEC

Factory wholesale Bean Seed Cleaning Machine - 5X-12 fine seed cleaner /grain seed cleaning machine for sesame chia seed sorghum soybean – SYNMEC Detail:

Introduction

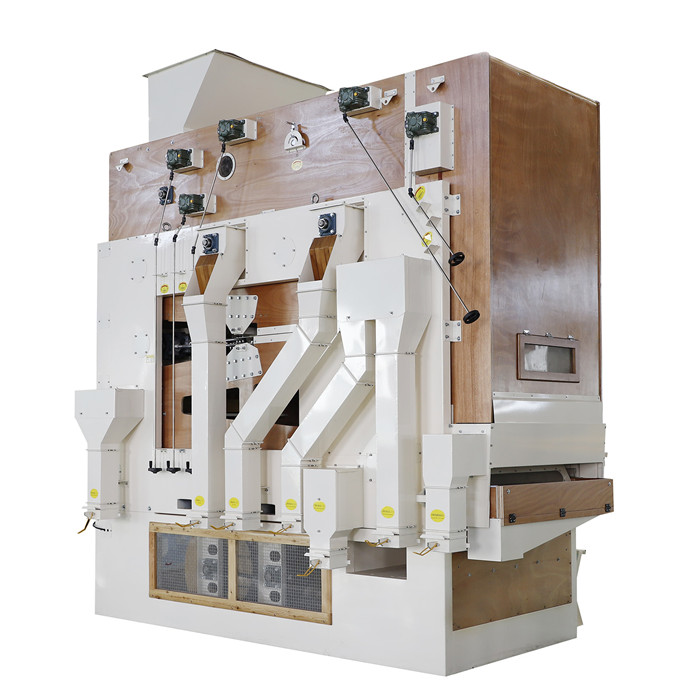

5X-12 Fine Seed Cleaner is used for cleaning and grading seeds, grains, cereals, and other granule products.

It can be equipped to suit a variety of special jobs and purposes.

Dust and light impurity are removed by aspirator fan and bottom blowing fan. Material falls on sieve layers and was separated by sieves according to width and thickness difference. All the oversize and undersize impurities were discharged from different outlets.

Features

5X-12 Fine Seed Cleaner is basic and most favourite cleaning machine in seed and grain industry of global market, with high efficiency, excellent performance, wide application.

It is suitable for processing all kind of seeds, cereals, grains species and crops, such as wheat, paddy, rice, barely, maize, millet, cumin, sunflower seed, soybean, coffee bean, cocoa bean, oil seeds, etc.

Customized screen hole size and various machine combinations allow the Fine Seed Cleaner to be used for a wide range of applications and increase grading efficiency.

Specification

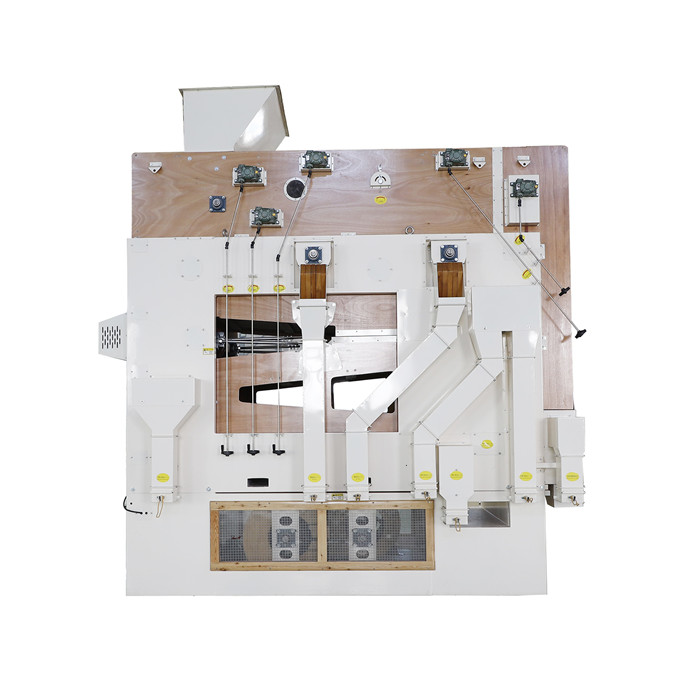

| Model | 5X-12 |

| Dimension(L×W×H) | 3720×1750×4060 mm |

| Overall weight | 3600 kg |

| Rated capacity | 12 Ton/h |

| Overall air volume | 12520 m3 |

| External air blower | 4-79N0-6A, 11 kW |

| Vibration sieve motor(gear motor) | 2.2 kW |

| Back lifting system motor | 3.0 kW |

| Feeding motor | 1.5 kW |

| Total Power | 6.7 kW |

| Air Blower Type | centrifuge air blower |

| Top air blower Rotary speed | 4-79NO6A,1400 r/min |

| Back lifting air blower Rotary speed | 100~1000 r/min |

| Screen Type | piercing screen |

| Each Screen Dimension (L×W) | 800×1250 mm |

| Frequency | 300(80~400) times/min |

| Amplitude | 30 mm |

| Layers and number | 5 layers,15 pieces |

| Total Screen Area | 15 m2 |

Product detail pictures:

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for Factory wholesale Bean Seed Cleaning Machine - 5X-12 fine seed cleaner /grain seed cleaning machine for sesame chia seed sorghum soybean – SYNMEC , The product will supply to all over the world, such as: Bangalore , Swiss , Moldova , Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.