China wholesale Maize Seed Processing Plant - 5XZS-10DGT Seed Cleaning & Processing Machine – SYNMEC

China wholesale Maize Seed Processing Plant - 5XZS-10DGT Seed Cleaning & Processing Machine – SYNMEC Detail:

The 5XZS-10DGT Seed Cleaning & processing machine is uniquely designed with air cleaning, gravity separating, vibratory sieve separating and grading maximizing the cleaning efficiency, minimizing the wear and tear and ease of removability & changeability.

Technical Data:

| Model: | 5XZS-10DGT |

| Function: | Wheat hulling (optional), air cleaning, pre-cleaning by two layers sieving trunks, two time gravity separating and four sieve layers fine sieve cleaning. |

| Size: | 8600X2300X3600mm |

| Capacity: | 10 ton/hour for seeds (count on wheat) |

| Cleaning rate: | >97% |

| Sieve cleaning type: | Rubber ball vibration |

| Noise: | <85dB |

| Electricity input: | 3 phase |

| Power: | 31.1Kw Wheat huller motor : 7.5Kw Bucket elevator: 1.1Kw Top air blower: 5.5Kw Pre-cleaner vibration motor:0.25Kw X 2 sets Gravity table: 7.5Kw X 2 sets Main sieving trunk vibration motor:0.75Kw X 2 sets |

Feature:

5XZS-10DGT Seed Cleaning & Processing Machine is designed with wheat hulling, air cleaning, pre-cleaning by two layers sieving trunk, two times gravity separating, vibration sieve cleaning and grading. This model consists of so many functions on one mobile type seed cleaner make it ideal for wider application.

Structure:

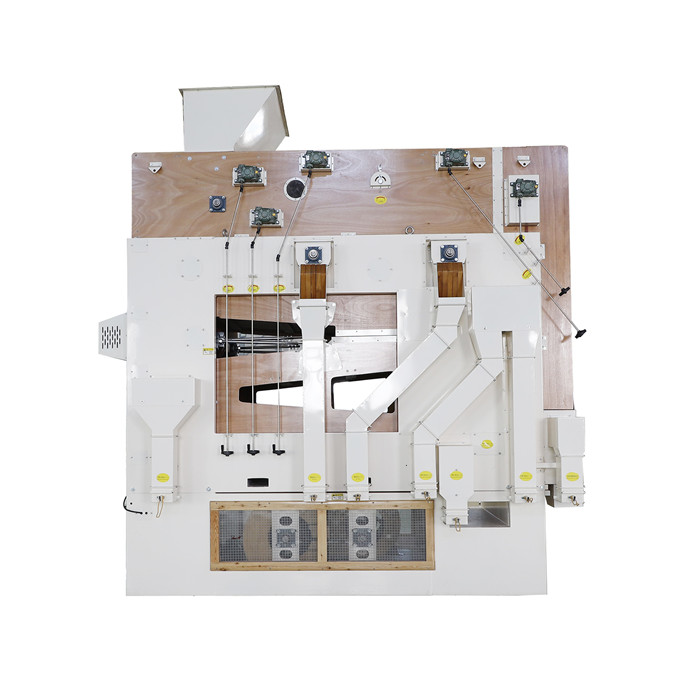

Multi functions combined in one machine

1.Wheat huller 2. Two sieving trunks 3. Air aspirator 4. Two Gravity tables 5. Air cleaning

Working flow:

Wheat are fed into wheat huller to hulling, then lifted up by bucket elevator, enter to pre-cleaning vibratory sieving trunk for quick removing small, large impurity, and light impurity, then wheat enter to two gravity tables for removing the bad seed (partially eaten, immature, insect damaged, sick seed, etc. ). Finally wheat enters to the second vibratory sieving trunk for removing oversized & undersize impurity again, also grading seed to different sizes. Wheat from outs becomes seed which can be sowed in ground directly.

Product detail pictures:

Related Product Guide:

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for China wholesale Maize Seed Processing Plant - 5XZS-10DGT Seed Cleaning & Processing Machine – SYNMEC , The product will supply to all over the world, such as: Australia , Swiss , Madrid , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.