China Cheap price Wheat Seed Processing Plant - Paddy Seed Processing Plant grain cleaning machines seed cleaning line – SYNMEC

China Cheap price Wheat Seed Processing Plant - Paddy Seed Processing Plant grain cleaning machines seed cleaning line – SYNMEC Detail:

SYNMEC offers customized designed seed processing plant for high productivity requests in various grain processing. On-site installation and frontline training service are available for clients. Our engineering term have a lot of experience of installation and adjustment. SYNMEC seed processing plant are now performing on five continents.

10T/H Barley Seed Processing Plant in Australia

In 2012, One Australian clients make an order from our factory. He wants to clean barley, wheat, oat seeds and sale them into marker at last. He had his own seed coating machine so we provide other machines for him.

This cleaning line includes:

1.5X-12 Fine seed cleaner: Cimbria type seed cleaner which can remove dust, light impurity, oversize and undersize impurities.

2.5XZ-10 gravity separator: American Oliver type which can remove partially eaten, immature, insect damaged and sick seed

3. DCS-50B bagging machine: Pack grain by the bag (10-50 kg per bag)

Other parts: air cleaning and dust removing system outside

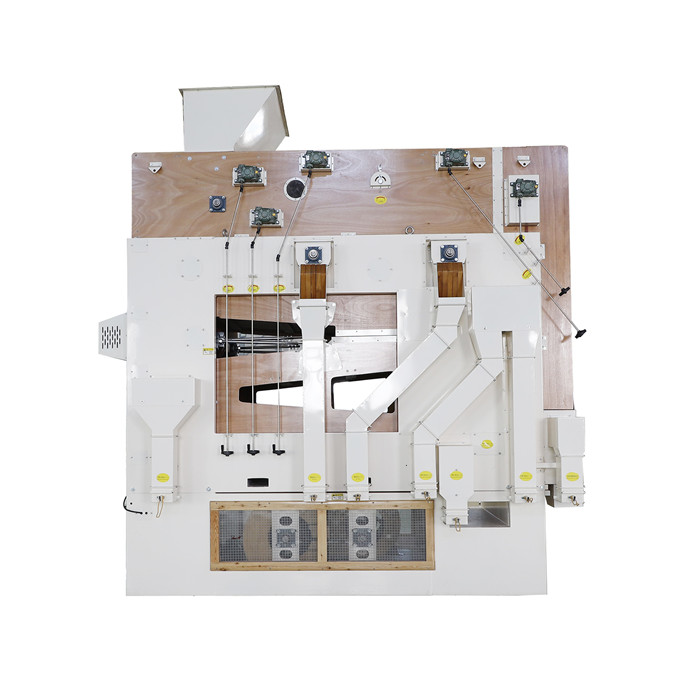

Drawing Design of Plant

High quality power control box with international standard.

This cleaning line include:

1. 5XZP Drum type pre cleaner

2. 5XTB-5 Grain Debearder

3. 5X-5 Fine seed cleaner

4. 5XWT-6 Thickness separator

5. 5XZ-6 Gravity separator

6. 5BY-5B Seed coating machine

7. DCS-50B Bagging machi

5X-12 Fine Seed Cleaner:

The 5X series Fine Seed Cleaner is a universal machine well suited for pre- and fine cleaning many different species of grain and seeds.

The standard design of the machine is provided with both pre- and after suction units. Quick screen changing from pre-cleaning into fine cleaning by the operator serves to optimize the cleaning tasks. The 5X series seed cleaner is a very competitive machine, both as regards price and capacity as well as function and operation.

The technology of the machine is thoroughly tested, which can be documented by many references all over the world.

It has high cleaning rate and it can be widely used for processing wheat, rice, corn, barley, peas and many other seeds also be used for all kinds of grain cleaning

| Model | 5X-12 |

| Dimension(L×W×H) | 3720×1750×4060 mm |

| Overall weight | 3600 kg |

| Rated capacity | 10 t/h |

| Overall air volume | 8200 m3 |

| External air blower | 4-72N0-6A, 7.5 kW |

| Vibration sieve motor(gear motor) | 2.2 kW |

| Back lifting system motor | 3.0 kW |

| Feeding motor | 1.5 kW |

| Total Power | 6.7 kW |

| Screen Dimension (L×W) | 800×1250 mm |

| Layers and number | 5 layers,15 pieces |

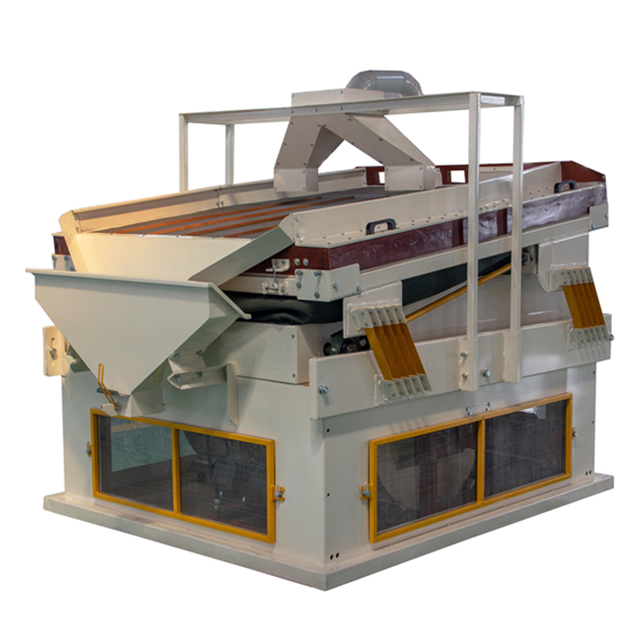

5XZ-10 Gravity Separator

5XZ-10 gravity separator is used to separate products with difference in specific weight.

The Gravity Separator is high standard American design, and have 6 indented mute air blower (often used in air conditioner), and the grain seeds can also come out from its end outlet also from its side.

Product detail pictures:

Related Product Guide:

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for China Cheap price Wheat Seed Processing Plant - Paddy Seed Processing Plant grain cleaning machines seed cleaning line – SYNMEC , The product will supply to all over the world, such as: Riyadh , Luxembourg , Yemen , Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!